Shrinivas Industries supplies only industrial quality products designed to stand up to the most rigorous applications. We get our raw material & products certified by accredited laboratory and the rigorous testing requirements of our numerous products are conducted under the watchful eye of the certifying bodies.

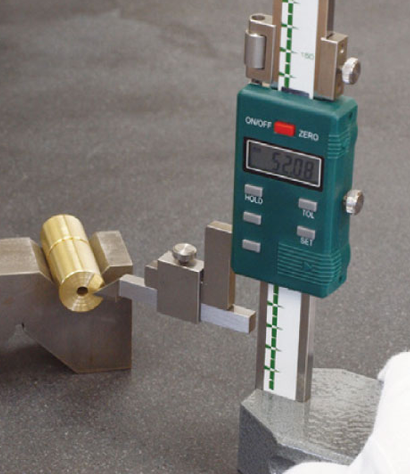

Continuous improvement is an ongoing process at our company. We have streamlined our quality assurance program to meet the ISO 9001:2015 standards. By implementing new and advanced stages to our inspection, testing and packaging procedures, our quality control system will meet or exceed ISO requirements and our customer needs. All products made or received by our company is subjected to thorough testing and inspections. We calibrate measuring instruments certified by NABL accredited laboratories.

We have dedicated quality control department, which ensures that each product is being manufactured as per standard engineering drawing provided by customer. Each process steps are being monitored and supervised by them throughout the process flow.

Basis customer’s need, we prepare the drawing and product process flow chart in AutoCAD Software. We share it to our production department to manufacture the same in-line with customer’s prerequisite. We are also able to produce any kind of customized metal components.

Within the scope of picking each order or suborder are directed to a particular packing location. The completeness of whole order can be checked here optionally. Than the packing list gets printed to be included into the packing and the whole order is packed and dispatched.

Shrinivas Industries is engaged in production of Metal Components with specialization in advanced Precision Turned Components.

Get Quick Quote